Muaj Me Me Neeg Hlau Caj Npab rau Yas Diav Txhaj Machinery Robot Joint Actuator Six Axis Neeg Hlau rau Daim Ntawv Thov Kev Lag Luam

Muaj Me Me Neeg Hlau Caj Npab rau Yas Diav Txhaj Machinery Robot Joint Actuator Six Axis Neeg Hlau rau Daim Ntawv Thov Kev Lag Luam

Lub ntsiab qeb

Muaj neeg hlau caj npab / Sib koom tes neeg hlau caj npab / Hluav taws xob gripper / ntse actuator / Automation daws

Daim ntawv thov

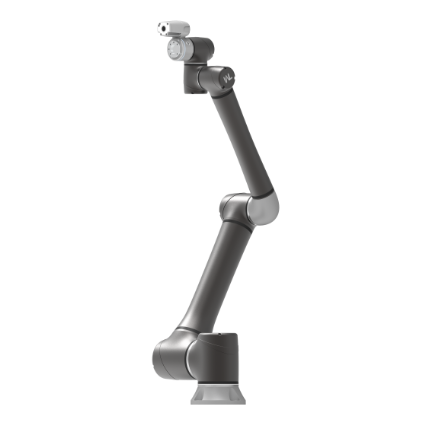

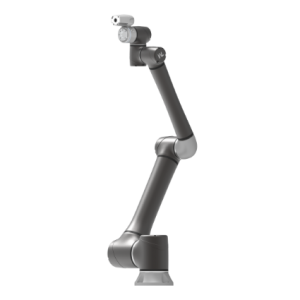

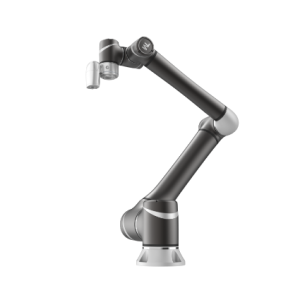

TM20 muaj peev xwm them nyiaj ntau dua hauv peb cov AI neeg hlau series. Qhov kev them nyiaj ntau ntxiv txog li 20kg, ua rau muaj kev sib txuas ntxiv ntawm cov neeg hlau automation thiab kev nce mus ntxiv rau kev xav tau ntau dua, kev siv hnyav dua nrog kev yooj yim. Nws yog tsim tshwj xeeb rau cov haujlwm loj tuaj tos, hnyav tshuab hnyav, thiab ntim ntim siab thiab palletizing. TM20 yog tsim rau ntau yam kev siv hauv yuav luag txhua qhov kev lag luam.

Nrog rau chav kawm-kev pom kev ua haujlwm, kev siv thev naus laus zis AI, kev nyab xeeb, thiab kev ua haujlwm yooj yim, AI Cobot yuav coj koj txoj kev lag luam mus ntxiv dua li yav dhau los. Coj automation mus rau qib tom ntej los ntawm kev txhawb nqa kev tsim khoom, txhim kho kom zoo, thiab txo cov nqi.

Qhia peb lub tswv yim tshiab thiab ua tau zoo 6-axis neeg hlau caj npab, tsim los hloov kho cov txheej txheem xws li kev thauj khoom thiab tshem tawm, polishing, tuav, txau, inverter vuam, thiab nplaim taws txiav. Nrog lub xeev-of-the-art technology thiab advanced automation nta, no ntau yam neeg hlau caj npab muaj unparalleled precision thiab productivity.

Lub peev xwm thauj khoom thiab tshem tawm ntawm peb cov neeg hlau caj npab ua kom cov txheej txheem tsim khoom sai thiab raug xa mus rau cov khoom thiab cov khoom ntawm ntau theem ntawm kev tsim khoom. Txawm hais tias nws tau muab cov khoom siv rau ntawm txoj siv conveyor lossis khaws cov khoom tiav los ntawm cov kab ntau lawm, lub caj npab neeg hlau no ua tau zoo hauv kev ua kom zoo rau kev thauj mus los thiab txo qis kev siv zog.

Nyob rau hauv lub realm ntawm polishing, peb robotic caj npab precision tswj thiab ceev ceev txav kom ib tug flawless tiav ntawm ntau qhov chaw. Nws cov programmed txav replicate cov intricacies ntawm tib neeg txhais tes piav qhia nrog unparalleled raug thiab sib xws, ua rau cov khoom zoo uas ua tau raws li qhov xav tau tshaj plaws cov qauv.

Kev tuav cov khoom hnyav thiab hnyav yog ua kom tsis muaj zog nrog lub caj npab robotic nqa peev xwm. Nruab nrog cov sensors siab heev thiab lub zog muaj zog, nws tuaj yeem siv zog ua haujlwm ntawm cov duab sib txawv thiab qhov ntau thiab tsawg, txo qhov kev pheej hmoo ntawm kev raug mob thiab nce kev ua haujlwm zoo hauv kev lag luam ib puag ncig.

Txau cov dej num ua kom meej dua thiab ua tau raws li kev sib xyaw ua ke ntawm lub tshuab nqus tsev twj tso rau ntawm caj npab robotic. Txawm hais tias nws yog pleev xim rau cov qauv tsim ntawm cov qauv nyuaj lossis sib npaug ntawm cov npoo loj, lub caj npab neeg hlau no ua kom muaj kev sib luag thiab kev ua tiav, txo qis kev siv nyiaj tsawg thiab siv cov peev txheej loj tshaj plaws.

Inverter vuam, txheej txheem tseem ceeb hauv ntau qhov kev lag luam, yog ua kom muaj txiaj ntsig zoo thiab txhim khu kev qha nrog peb cov neeg hlau caj npab. Nrog rau kev muaj peev xwm rov ua dua cov qauv vuam nyuaj, lub caj npab xa cov welds zoo ib yam thiab zoo, txo tib neeg kev ua yuam kev thiab nce kev tsim khoom.

Tsis tas li ntawd, cov nplaim taws txiav lub peev xwm ntawm lub caj npab neeg hlau no tso cai rau kev txiav hlau kom raug thiab ua tau zoo, tshem tawm qhov xav tau ntawm kev siv tes ua haujlwm thiab ua kom muaj kev nyab xeeb hauv qhov chaw muaj kev phom sij.

Peb lub caj npab neeg hlau tau nruab nrog cov cuab yeej inverter siab heev thiab cov kev tswj xyuas ntse, ua kom muaj zog ua haujlwm tau zoo thiab meej txav. Qhov no txhais ua kev txuag nqi tseem ceeb thiab nce kev tsim khoom rau kev lag luam.

Nyob rau hauv xaus, peb 6-axis neeg hlau caj npab yog ib tug kev ua si-hloov nyob rau hauv industrial sector, muab ib tug ntau yam ntawm muaj peev xwm uas txhim kho ntau yam txheej txheem. Nrog rau qhov tsis sib xws, kev ua tau zoo, thiab kev siv ntau yam, lub caj npab neeg hlau no txhawb kev lag luam kom ua tiav cov txiaj ntsig zoo, txuag nqi, thiab nyob ua ntej hauv thaj chaw tsim khoom puas tau hloov zuj zus.

Nta

SMART

Yav tom ntej-pov thawj Koj Cobot nrog AI

• Automated kho qhov muag tshuaj xyuas (AOI)

• Kev lees paub zoo & kev sib raug zoo

• Ua kom ntau lawm efficiency

• Txo cov nqi khiav lag luam

SIJ HAWM

Tsis xav tau kev paub

• Graphical interface rau programming yooj yim

• Txheej txheem-oriented editing workflow

• Kev taw qhia yooj yim rau kev qhia txoj haujlwm

• Ceev nrooj calibration nrog calibration board

SAFE

Kev sib koom tes kev nyab xeeb yog peb qhov tseem ceeb

• Ua raws li ISO 10218-1: 2011 & ISO / TS 15066: 2016

• Nrhiav kev sib tsoo nrog nres thaum muaj xwm ceev

• Txuag tus nqi thiab qhov chaw rau kev thaiv & laj kab

• Teeb tsa kev txwv ceev hauv qhov chaw ua haujlwm sib koom tes

AI-powered cobots paub txog qhov muaj thiab kev taw qhia ntawm lawv ib puag ncig thiab qhov chaw los ua qhov kev soj ntsuam pom thiab ua haujlwm dynamic xaiv thiab qhov chaw. Yooj yim siv AI rau cov kab ntau lawm thiab ua kom cov khoom tsim tau, txo tus nqi, thiab txo lub sij hawm voj voog. AI lub zeem muag tseem tuaj yeem nyeem cov txiaj ntsig los ntawm cov tshuab lossis cov cuab yeej ntsuas thiab txiav txim siab raws li qhov tsim nyog.

Dhau li ntawm kev txhim kho cov txheej txheem automation, AI-tsav tsheb cobot tuaj yeem taug qab, txheeb xyuas, thiab sib xyaw cov ntaub ntawv thaum lub sijhawm tsim khoom los tiv thaiv qhov tsis xws luag thiab txhim kho cov khoom zoo. Yooj yim txhim kho koj lub Hoobkas automation nrog cov txheej txheem AI ua tiav.

Peb cov neeg hlau sib koom tes tau nruab nrog lub zeem muag kev sib koom ua ke, muab cov cobots muaj peev xwm pom lawv qhov chaw nyob ib puag ncig uas txhim kho cov peev txheej cobot. Robot tsis pom kev lossis muaj peev xwm "pom" thiab txhais cov ntaub ntawv pom rau hauv cov lus txib yog ib qho ntawm cov yam ntxwv uas ua rau peb zoo dua. Nws yog qhov hloov pauv kev ua si rau kev ua haujlwm kom raug hauv cov chaw ua haujlwm hloov pauv hloov pauv, ua kom cov haujlwm ua haujlwm tau zoo dua, thiab cov txheej txheem automation zoo dua.

Tsim los nrog cov neeg siv thawj zaug hauv siab, kev paub txog kev ua haujlwm tsis yog qhov yuav tsum tau pib nrog AI Cobot. Ib qho intuitive click-and-drag tsab ntawv tsa suab siv peb cov programming software txo qhov nyuaj. Peb patented thev naus laus zis tso cai rau cov tswv lag luam uas tsis muaj kev paub coding los ua qhov project luv li tsib feeb.

Inherent kev nyab xeeb sensors yuav nres AI Cobot thaum kuaj pom lub cev, txo qhov kev puas tsuaj rau qhov chaw tsis muaj siab thiab nyab xeeb. Koj tuaj yeem teeb tsa kev txwv ceev rau cov neeg hlau kom nws tuaj yeem siv rau ntau qhov chaw nyob ib sab ntawm koj cov neeg ua haujlwm.

Yam khoom

Specification Parameter

| Qauv | TM 20 | |

| Qhov hnyav | 32.8 KWG | |

| Maximum Payload | 20 KG | |

| Mus txog | 1300 hli | |

| Kev sib koom ua ke | j1,j 6 | ± 270 ° |

| J2, J4, J 5 | ± 180 ° | |

| J3 | ± 166 ° | |

| Ceev | J1,J 2 | 90 ° / s |

| J3 | 120 ° / s | |

| J4 | 150 ° / s | |

| J5 | 180 ° / s | |

| J6 | 225 ° / s | |

| Hom Ceev | 1.1 m / s | |

| Max. Ceev | 4 m/s | |

| Rov ua dua | ± 0.1 hli | |

| Degree ntawm kev ywj pheej | 6 kev sib hloov sib txuas | |

| I/O | Tswj lub thawv | Cov tswv yim digital: 16 Cov txiaj ntsig digital: 16 Analog tswv yim: 2 Analog tso zis: 1 |

| Tool Conn. | Cov tswv yim digital: 4 Digital tso zis: 4 Analog tswv yim: 1 Analog tso zis: 0 | |

| I/O Power Supply | 24V 2.0A rau lub thawv tswj thiab 24V 1.5A rau cov cuab yeej | |

| IP Classification | IP54 (Robot Arm); IP32 (Control Box) | |

| Kev siv fais fab | Hom 300 watts | |

| Kub | Cov neeg hlau tuaj yeem ua haujlwm hauv qhov kub ntawm 0-50 ℃ | |

| Kev huv huv | ISO Class 3 | |

| Fais fab mov | 100-240 VAC, 50-60 Hz | |

| I/O interface | 3xCOM, 1xHDMI, 3xLAN, 4xUSB2.0, 2xUSB3.0 | |

| Kev sib txuas lus | RS232, Ethemet, Modbus TCP / RTU (tus tswv & qhev), PROFINET (Yeem), EtherNet / IP (Yeem) | |

| Programming Ib puag ncig | TMflow, flowchart raws | |

| Daim ntawv pov thawj | CE, SEMI S2 (Option) | |

| AI & Vision *(1) | ||

| AI Function | Classification, Object Detection, Segmentation, Anomaly Detection, AI OCR | |

| Daim ntawv thov | Muab tso rau hauv, 1D / 2D Barcode nyeem ntawv, OCR, Defect Detection, Measurement, Assembly Check | |

| Positioning raug | 2D qhov chaw: 0.1mm *(2) | |

| Qhov muag hauv tes (Ua hauv) | Nws pib tsom xim carmera nrog 5M daws teeb meem, Ua haujlwm nrug 100mm ~ ∞ | |

| Qhov muag rau tes (yeem) | Txhawb 2xGigE 2D lub koob yees duab lossis 1xGigE 2D Lub Koob Yees Duab + 1x3D Lub Koob Yees Duab *(3) | |

| *(1)Tsis muaj qhov pom kev pom neeg hlau caj npab TM12X, TM14X, TM16X, TM20X kuj muaj. *(2)Cov ntaub ntawv nyob rau hauv cov lus no yog ntsuas los ntawm TM kuaj thiab qhov ua hauj lwm nrug yog 100 hli. Nws yuav tsum tau muab sau tseg tias nyob rau hauv cov ntaub ntawv siv tau, cov txiaj ntsig tseem ceeb yuav txawv vim muaj qhov sib txawv xws li qhov chaw nyob ntawm lub teeb pom kev zoo, cov yam ntxwv ntawm cov khoom, thiab cov txheej txheem kev pom kev uas yuav cuam tshuam qhov kev hloov ntawm qhov raug. *(3)Xa mus rau lub vev xaib raug cai ntawm TM Plug & Ua Si rau lub koob yees duab qauv sib xws rau TM Robot. | ||

Peb Kev Lag Luam